Electrical Cable Types, Sizes, and Installation

An electrical cable has the purpose of transporting electrical energy from one point to another. Depending on their final application, cables can have different configurations, always basing their design on national and international regulations.

Electrical cable Voltage

An electric cable is measured in volts and, depending on these, they are categorized into one group or another:

Low voltage cables (up to 750 V): in a variety of applications, and with thermoplastic and thermoset coatings. They are designed and built according to harmonized standards.

Low Voltage cables (up to 1,000 V): (also called (0,6/1 kV) The cables in this section are used for industrial power installations in various fields (general industry, public installations, infrastructures, etc.). They are designed according to international standards

Medium Voltage cables: from 1 kV to 36 kV. They are used to distribute electricity from electrical substations to transformer stations.

High Voltage cables: from 36 kV. They are used to transport electricity from the generating plants to the electrical substations.

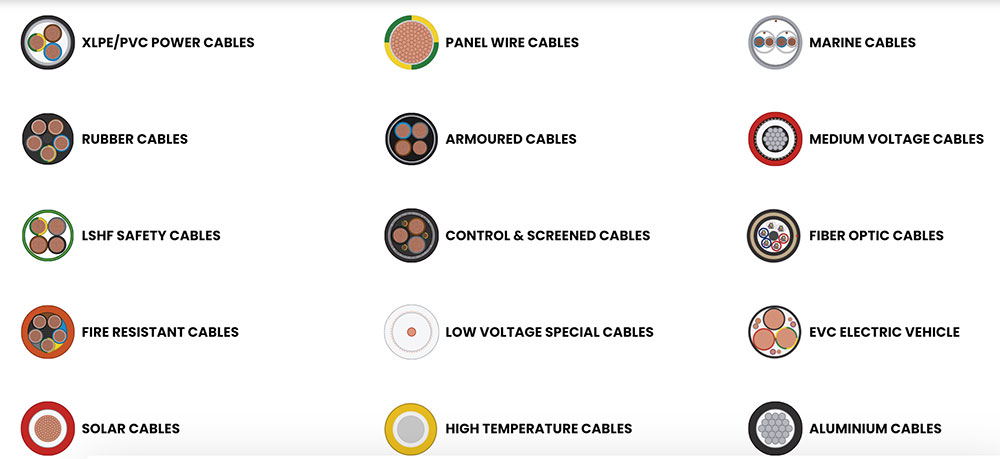

Types of electrical cable by their use

Low voltage cables

Cables for electric panels

Flexible cables for wiring electric cabinets. These electric cables are especially suitable for domestic use, for installation in public places and for internal wiring of electrical cabinets, switch boxes and small electrical appliances.

Power cables

Energy cables for industrial facilities and public places. It is common to find power cables in applications for power transmission in all types of low voltage connections, for industrial use and for variable frequency drive (VFD).

Armoured cables

Cables with aluminium or steel reinforcement for installations with risk of mechanical aggression. It is also common to find armoured cables in places where rodents are present, as well as in installations in premises with a risk of fire and explosion (ATEX).

Rubber cables

The use of extra flexible rubber cables is very varied. We can find rubber cables in fixed industrial installations as well as in mobile service. Welding cables should have a rubber sheath, which allows high currents to be transmitted between the welding generator and the electrode.

Halogen-free cables

High Security Halogen Free (LSZH) Cables with low smoke and corrosive gas emission in case of fire are suitable for use in wiring of electrical panels and public places, installations of all kinds in public places, individual derivations, emergency circuits, public distribution networks and also for mobile service.

Fire resistant cables

These cables are specially designed to transmit electrical energy in the extreme conditions that occur during a prolonged fire, guaranteeing supply to emergency equipment such as signalling, smoke extractors, acoustic alarms, water pumps, etc. Their use is recommended in emergency circuits in places with public concurrence.

Control cables

Control cables for fixed or mobile installations should be extremely flexible, as they are mainly designed for small household appliances, for the interconnection of machine parts used for manufacturing, for signalling and control systems, for the connection of motors or frequency converters, for signal transmission where the voltage induced by an external electromagnetic field may affect the transmitted signal or for power supply connections to avoid generating electromagnetic fields.

Instrumentation cables

These are flexible and shielded cables for the transmission of signals between equipment in industrial installations. Especially suitable for optimum data transmission in environments with a high level of electromagnetic interference.

Solar cables

These cables are particularly suitable for connecting photovoltaic panels, and from the panels to the DC to AC inverter. Thanks to the design of their materials and their cover, which is especially resistant to solar radiation and extreme temperatures, they can be installed outdoors with full guarantees.

Special cables

There is a wide variety of electric cables for special installations such as: temporary light garland installations at trade fairs; connections for overhead cranes, hoists and lifts; applications in submerged pumps and drinking water areas such as aquariums, purification systems, drinking water fountains or in swimming pools for lighting, purification and cleaning systems.

Aluminium cables

Aluminium cables for power transmission are suitable for fixed installation indoors, outdoors and/or underground.

Medium Voltage Cables

RHZ1

Medium Voltage Cable type RHZ1 with XLPE insulation, halogen free and non flame and/or fire propagating. They are cables perfectly adapted for the transportation and distribution of energy in Medium Voltage networks.

RHVhMVh

Copper and aluminium medium voltage cable for special applications. Especially recommended for installations where there is a risk of presence of oils and chemical agents of the hydrocarbon type or their derivatives.

Components of an electrical cable

An electric cable consists of:

Electric conductor: which channels the flow of electricity

Insulation: it covers and contains the electric flow in the conductor.

Auxiliary elements: that protect the cable and guarantee its longevity.

Outer sheath: it covers all the mentioned materials protecting them from the outside.

Types of electric conductors

Bare wire conductor: single wire in solid state, not flexible and without coating.

Aluminum electrical conductors: in some cases, aluminum conductors are also used, despite the fact that this metal is 60% worse conductor than copper.

Copper electrical conductors: the most commonly used material.

Flexible copper wire conductor: it is a set of fine wires covered by an insulating material. They are flexible and malleable.

Single-core cable: a cable with a single conductor.

Multi-core cable: a cable that has several conductors.

Types of insulation for electric cables

The insulation consists of placing an insulating coating on the conductor to prevent current leakage. They are classified into two large groups: thermoplastic and thermoset.

1. Thermoplastic insulation

They are most common in the manufacture of electrical cables are:

PVC:Polyvinyl chloride

Z1: Polyolefins

PE: Linear polyethylene

PU: Polyurethane

2. Thermosetting insulation

The most common are:

EPR: Ethylene Propylene

XLPE: Crosslinked Polyethylene

SI: Silicone

PCP: Neoprene

Types of metal protections for electrical cables

In some cases, the cables may have metal shields.

Screens: these are electrical metal protections applied to isolate the signals that pass through the interior of the cable from possible external interference.

Armours: these are mechanical protections that protect the cable from possible external aggressions: animals, blows, etc.