Power cables are ubiquitous for different industrial applications. In cases where ordinary power cables cannot operate under certain harsher conditions, H07RN-F neoprene cables become an attractive choice.

What does H07RN-F mean?

H – conformity to harmonized standards (set by CENELEC that standardizes electrotechnical specifications)

07 – voltage rating is 450/750V

R – EPR insulation

N – PCP jacket

F – Flexible copper conductors

H07RN-F neoprene has the following properties that make it a good heavy-duty electrical cable:

Flexible

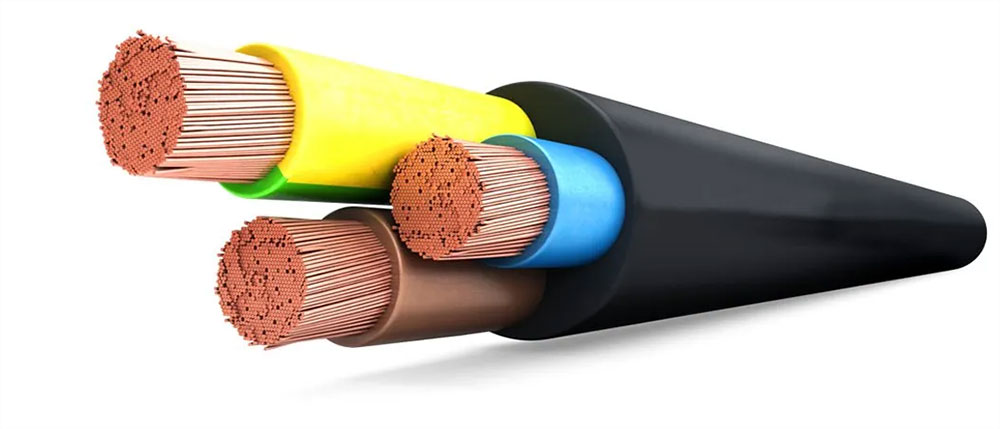

In addition to the rubber properties, which give it good flexibility, neoprene cables also use Class 5 copper conductors, which indicate finer copper strands to make up the conductor core. This prevents the cable with high flexibility properties and allows neoprene cables to be installed either as a fixed or mobile cable.

Chemical Resistance

The cables have great chemical resistance and thus can be installed under adverse conditions such as oily, acidic, and alkaline environments.

Scratch Resistance

Neoprene has superior resistance to abrasions and scratches. Therefore, they are suitable and commonly used at worksites.

Wide Temperature Range

Compared to standard PVC insulated cables, which have a temperature rating of 5°C to 70°C, neoprene cables have a larger range of temperature rating of -25°C to 90°C; under high-temperature conditions, the neoprene cable insulation will not melt, and at low-temperature conditions, neoprene cables can still maintain its flexibility and not crack. It is thus a popular choice for use under environmental hazards, including water, sunlight, sand, and snow.

Given the distinct advantages of neoprene cables, they are popular for industrial use and use in worksite equipment such as power tools, pumps and generators.

For more information on how EPR insulation may compare with other common cable materials, we have a summarized table for reference.